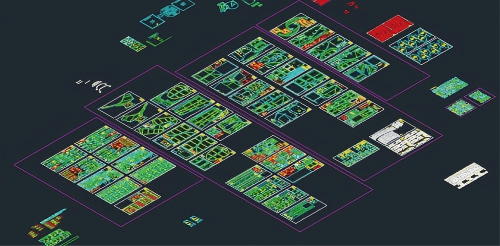

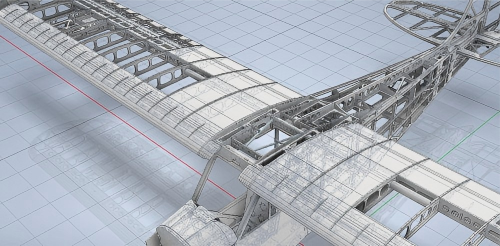

All designs are derived from a comprehensive digital engineering workflow. From individual components to the integral airframe structure, all elements are systematically planned and verified via professional engineering software to ensure logical rigor and structural rationality. We provide a full-aircraft 3D documentation system, intended to transform your assembly process from "reliance on empirical experience" to "comprehension and adherence to a clear engineering framework."

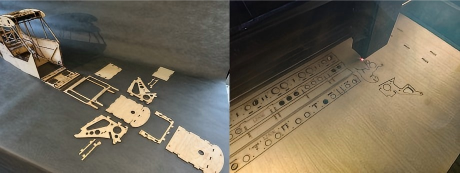

Each component undergoes precision design and machining, enabling you to effortlessly achieve the predefined accuracy and operational performance. This does not diminish the hands-on pleasure; instead, it liberates you from tedious post-processing adjustments, allowing you to focus more on experiencing structural mechanics and the inherent wisdom of the assembly process itself.

Process Consistency Under a Unified Digital Source

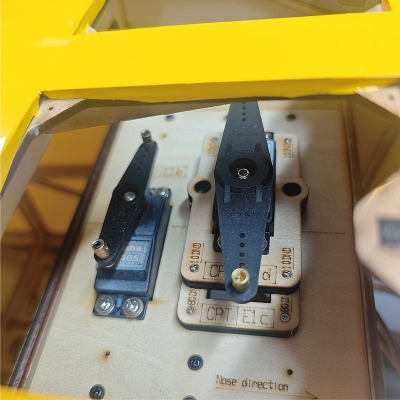

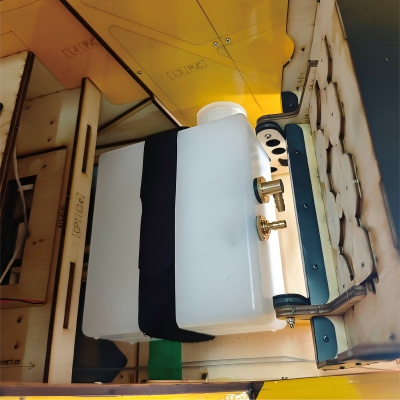

Maintenance-Oriented Design for Long-Term Utilization

We have incorporated your long-term usage experience into the initial design phase. The model is configured with rational inspection hatches and modular compartments, and most structural assemblies are detachable to facilitate routine maintenance and parameter adjustments. This enables the model not only to "emulate the flight performance of a full-scale aircraft" but also to "match the operational usability of a full-scale aircraft," becoming your trustworthy and durable flying companion.

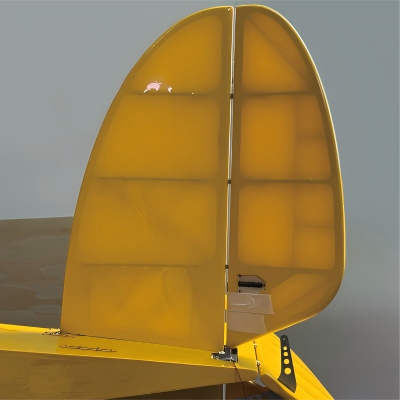

Visual Optimization Based on Artistic Judgment

On the premise of upholding the inherent charm of the full-scale aircraft, we have implemented scale-adapted visual optimizations on local details. Through subtle adjustments to contour lines and proportional dimensions, the model exhibits enhanced artistic expressiveness, ensuring an elegant aerodynamic posture with details integrating seamlessly with the overall design. It remains an exquisite and appreciable engineering artwork even in a stationary state.

Aerodynamic Adaptation for Model-Scale Reynolds Number

The aerodynamic design is not a mere duplication of full-scale aircraft data; instead, it is optimized for the model-scale Reynolds number based on a thorough comprehension of its inherent flight demeanor. Without compromising scale fidelity, targeted adjustments are made to airfoil profiles and aerodynamic details to achieve more stable and predictable low-speed flight characteristics, restoring that composed and classic flight posture. (E.g.: The main wing is moderately thickened to enhance lift-to-drag ratio, and the nose cowl dimensions are optimized to improve heat dissipation efficiency)

Configuration Verification Oriented to Reliable Flight Performance

All design parameters are validated through extensive flight test campaigns. The equipment layout and trim recommendations we provide are derived from accumulated real-flight data, aiming to minimize your system tuning costs and initial flight risks. What we pursue is not extreme performance metrics, but a predictable, repeatable, and reliable flight experience, enabling you to fly with confidence, willingness, and consistency.

Altitude Lab

More than a scale model—it is about condensing the essence of

flight into a manageable scale that you can truly master.

1/4 RC PIPER J-3 CUB ARF Ver.

Technical Parameters

Product Parameters

Wingspan :2680 mm

Length :1780 mm

Empty weight : 5.8 kg

For scale flight, a 40–55 cc multi-cylinder or single-cylinder engine is recommended. For aerobatic flight, a 50–85 cc engine is recommended.

The ARF kit includes all standard components, plus pre-covered and precision-machined parts, fully painted finished components, and a fully installed navigation light system.

The ARF kit does not include the engine, electronic equipment, or the instrument-seat lighting system. The engine cowling must be drilled according to engine requirements, and the fuselage, wings, and landing gear must be assembled in accordance with the instructions.

Package Dimensions

L 1700 mm × W 800 mm × H 500 mm, Weight: 18 kg